P500 RFID INLAY INSERTION EQUIPMENT

Dry Inlay Insertion offers multi lane, high speed, accurate placement.

The liner receives a pattern coating of hot melt adhesive to eliminate an adhesive void in the area of the inlay.

P500 RFID Inlay Insertion Equipment

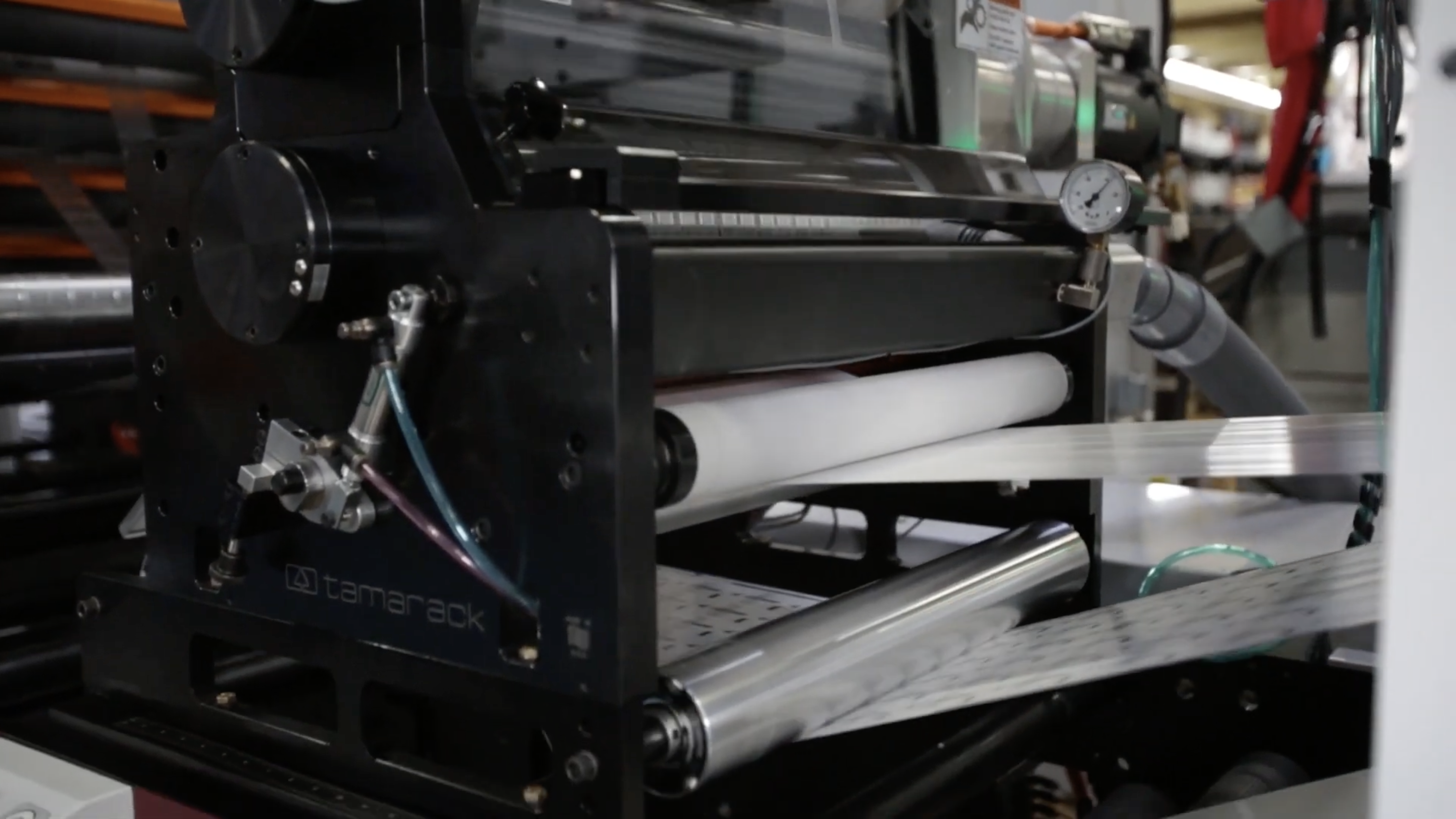

The P500 RFID inlay insertion equipment by Tamarack produces RFID labels, tickets, and tags in a single pass on your new or existing Flexo press.

The P500 RFID is servo driven, simplifying integration into your press. The P500 RFID is typically installed after the press print stations and before the finishing section

Inserts lower cost, dry inlays; wet inlay insertion is also available

Operator-friendly controls, fast set-up and simple web path allow productive completion of short run jobs and trials

Options:

Static elimination system

Reader, marker, encoder integration

-

The P500 RFID inlay insertion equipment by Tamarack produces RFID labels, tickets, and tags in a single pass on your new or existing Flexo press.

Tamarack Products is a leading manufacturer of RFID inlay insertion equipment that accommodate all inlay sizes. With the P500 RFID, converting smart labels inline on your press is easy and efficient at speeds up to 500 ft/min (150 m/min). The P500 RFID tag manufacturing machine affixes inlays from 3/8″ to 13″ wide and from 3/8″ to 9″ long, meeting the requirements of all inlay products.

P500 RFID Inlay Insertion Equipment

The P500 RFID label manufacturing machine provides straight-forward, simple set-up with a user friendly touch-screen control to enter job parameters. Easily affix RFID inlays with excellent ± 1/64″ (.4 mm) registration. Affix roll-fed materials with Servo-driven technology and a rotary, vacuum cylinder approach. Tamarack offers the ability to customize your RFID inlay labeling system to meet your specific requirements.

Modular RFID Ticket Manufacturing Machine

The Servo-driven technology of Tamarack’s RFID ticket manufacturing machine provides flexibility with high productivity. The affixing equipment can be adapted to a different part of the press, or relocated to a different flexo press, as smart label production requirements change. The servo-driven components allow inlay affixing on all label repeat sizes without the need for gear changes or cylinder changes.

The RFID inlay insertion equipment is designed to begin with simple, one-wide operation with the ability to add components as production demands increase. Support growth with Tamarack’s P500 RFID as a second unwind/feed station can be added for two-stream operation. Inlay verification systems can be accommodated and splicing units can be added to avoid stopping for inlay roll changes.

P500 RFID Inlay Insertion Applications

The P500 RFID converting machine by Tamarack is designed, engineered, and manufactured for long-lasting, high-quality, precision performance for RFID labels, tags, and tickets. The P500 RFID inlay insertion system produces a wide variety of face stocks, with UHF or HF inlays meeting the needs of many applications including RFID labels, tags, and tickets for uses such as:

Airline luggage tags

Apparel labels

Asset tracking labels to track inventory

Logistics labels

Pharmaceutical labels

Tickets for events or transportation

Ski-lift tickets

Many other RFID solutions

-

RFID Labels

RFID labels are produced with a variety of face stocks, and UHF, NFC/HF inlays are inserted to meet the requirements of specific applications. Any RFID form factor, wet or dry, can be inserted to produce RFID labels:

Logistics labels: meet retailer mandates for case and pallet shipping labels

Asset tracking labels: produce RFID labels for warehouse, inventory and production tracking

Airline bag tags: provide luggage tracking and enhance security

Apparel labels: improve inventory management and merchandising with item-level tagging.

Library labels: locate, track and manage library materials

File labels: track legal and patient files

Pharmaceutical and nutraceutical labels: provide item-level tracking for inventory, anti-counterfeiting and e-pedigree requirements.

RFID Tags

RFID inlays are inserted between top-of-tag and bottom-of-tag plies to produce tag and ticket constructions:

Apparel tags: improve inventory management and merchandising with item-level tagging. Inventory counts are completed with dramatic time savings, resulting in rapid ROI.

Tickets: meet transportation, leisure and event ticketing requirements for patron convenience, security and anti-counterfeiting

Ski-lift tickets: for patron convenience and enhanced security

Other RFID constructions

The applications for RFID are increasing! Please contact us to discuss your application and production requirements.