Tamarack Products Inc. manufactures innovative finishing equipment for the business forms and packaging industries.

Tamarack's patch application equipment enhances the appearance and function of business forms, folding cartons, and flexible packaging by affixing labels, holograms, scratch-off patches, windows, hang-tag reinforcements, security/anti-theft devices, integral cards, and integral labels. Off-line equipment, as well as in-line modules for presses and folder/gluers, are available.

MVW OFFLINE RFID INLAY INSERTION EQUIPMENT

The Tamarack MVW off-line RFID insertion machine produces RFID labels, tickets, and tags. A complete offline platform, the MVW is configured to your specific requirements with the following features:

Designed to insert the inlay into a pre-printed web, the MVW includes a re-registration system to assure that the inlay is placed in register to the print.

Configured to insert wet inlays, dry inlays, or both.

Multiple lanes for high volume production.

User-friendly operator interface.

P500 RFID INLAY INSERTION EQUIPMENT

The P500 RFID inlay insertion equipment by Tamarack produces RFID labels, tickets, and tags in a single pass on your new or existing Flexo press.

The P500 RFID is servo driven, simplifying integration into your press. The P500 RFID is typically installed after the press print stations and before the finishing section

Inserts lower cost, dry inlays; wet inlay insertion is also available

Operator-friendly controls, fast set-up and simple web path allow productive completion of short run jobs and trials

VISTA INLINE WINDOW PATCHING EQUIPMENT

Tamarack’s Vista Window Patcher in-line window patching equipment patches windows for both high-volume and short-run folding carton jobs. Efficiently affix liners, susceptor patches, and rigid windows for specialty cartons with the Vista®.

Quick set-up and clean-up

Excellent patch registration accuracy

User friendly, instructional touch screen provides simple entry and job parameter recall

Adhesive is printed directly on the window film, resulting in neat glue lines, reduced patch size, and higher speeds

Standard configuration provides patching for windows up to 14” wide. Wider systems, up to 18” wide, are available.

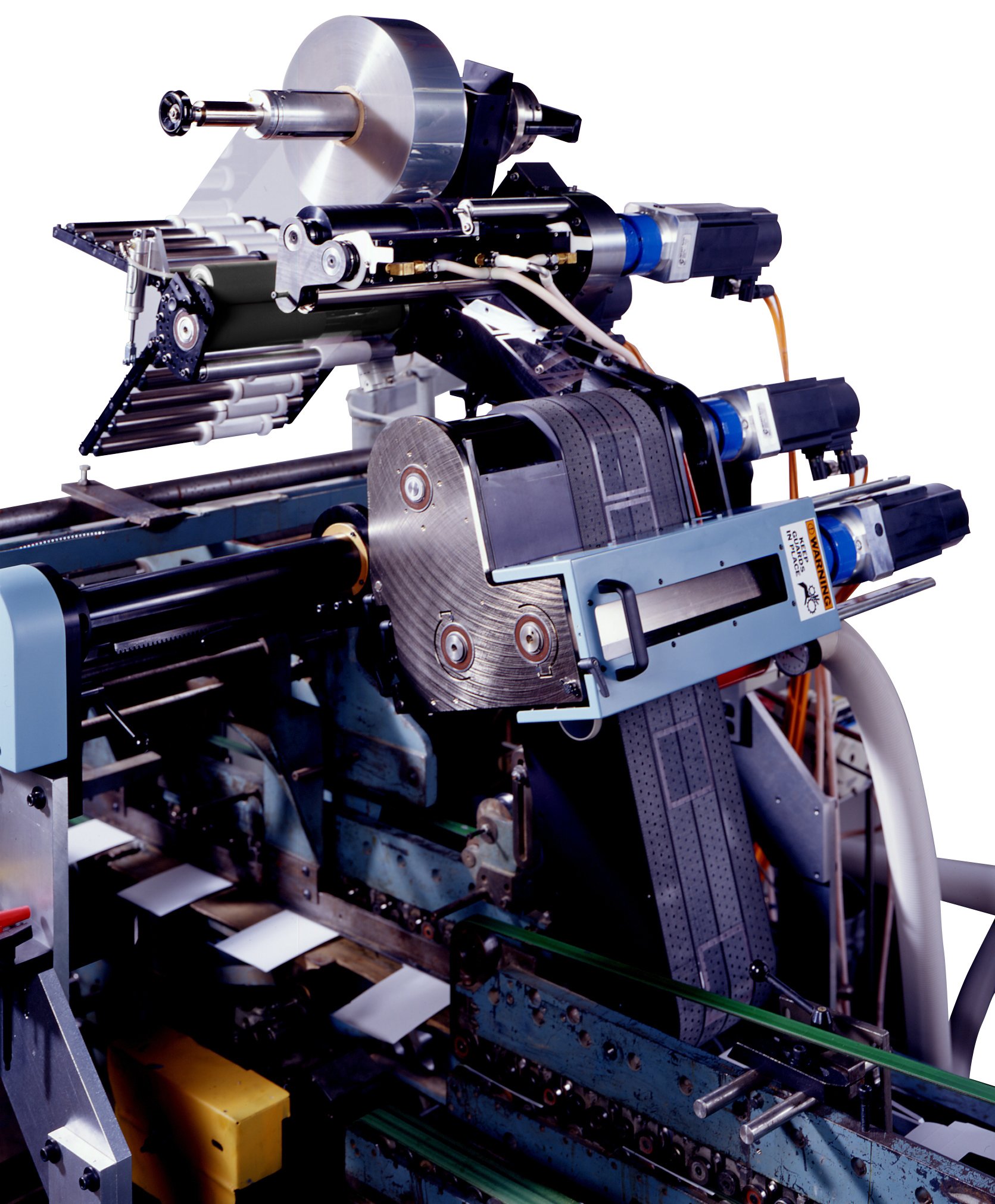

VERSA WEB P500 INTEGRATED LABELLING SYSTEM

The Versa Web P500 is an inline integrated labeling machine that can affix transfer tapes and laminates for integral or integrated forms, labels and cards, affix holograms and scratch-off materials for promotional products, or affix windows.

The P500 is servo driven—simplifying integration into your press. The P500 is typically installed after the press print stations and before the finishing section.

Available in 13” (330mm) or 20” (508mm) widths.

Speeds up to 500 ft/min (150 m/min).

Excellent +/- 1/32” (.8mm) patch registration accuracy.

Single- or multiple-wide patch affixing.

The press remains available for standard, non-affixed jobs.

The P500 can be upgraded to affix RFID inlays.

VERSA WEB SE WEB FINISHING SYSTEM

The Versa Web SE offline integral labeling machine produces integral or integrated forms, labels, and cards, and affixes scratch-off, magnet, label, hologram and other roll-fed materials to business forms, direct mail, and promotional products.

Speeds up to 500 ft/min (150 m/min)

19″ (480 mm) web width for one- or two-wide production

Excellent +/- 1/32″ (.8 mm) registration accuracy; patches can be positioned close to perforations or form edges

No cut-off cylinder changes

Hot melt system option coats release liner with pressure-sensitive adhesive, resulting in low cost integral label production

SE Transport system available with pin tractor or pinless (low tension) configurations

Peel system available to affix plastic cards and other liner-fed products.